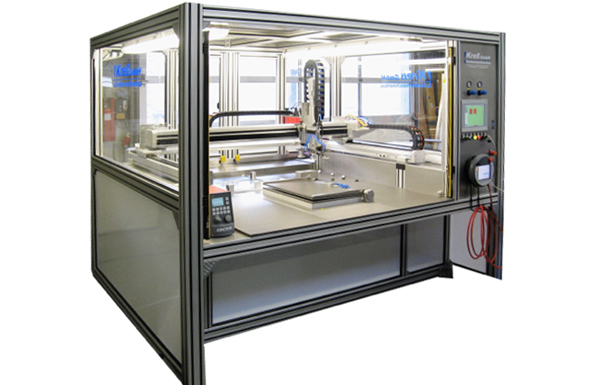

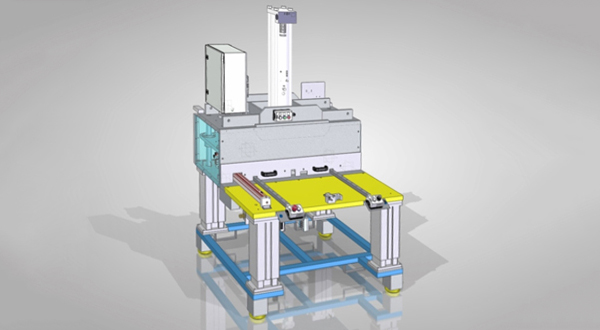

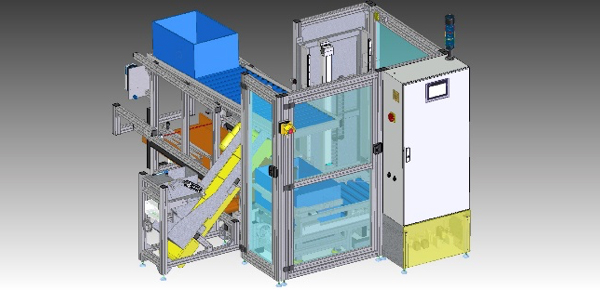

Pressure test bench for pressure testing cables. The cables are made from plastic, rubber, metal or a combination of these. Pressure testing can be carried out both with vacuum pressure or also positive pressure to 40 bar. It is possible to use water, air or Helium as the test medium.

The parts are inserted and fixed by hand. Pressure testing, pressure loss and flow testing can be carried out. Evaluation is carried out using a test unit.

The cables which are tested and are OK can be printed where required. Component specific text or a data matrix code can be printed on the item. An inkjet printer is used for the printing process.

Customers

Data

- It is possible to carry out pressure testing up to 40 bar.

- Printing on the test pieces which are OK

- Compact design of the test bench